Gravimetric Adsorption Energy Distribution

November 25, 2013

Executive Summary

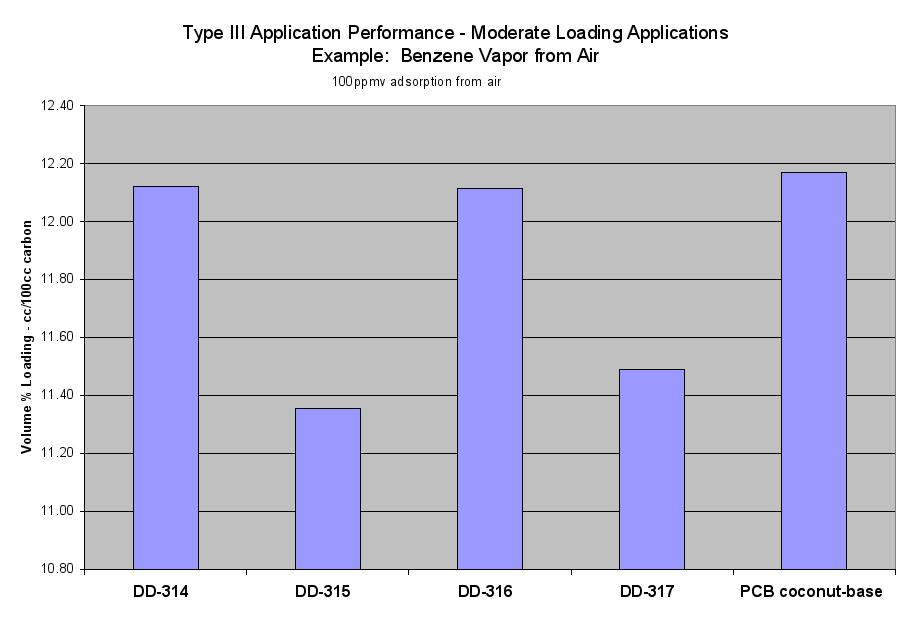

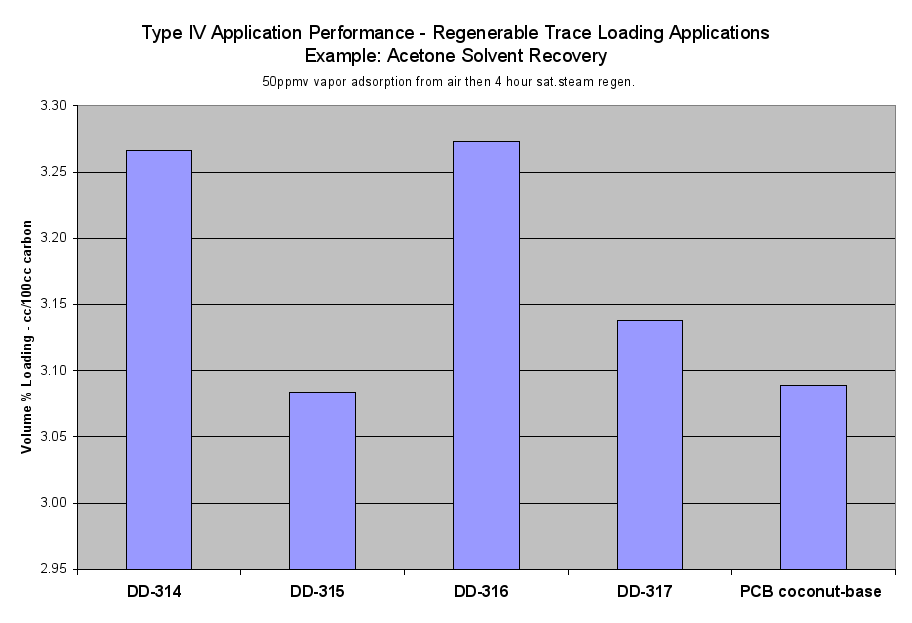

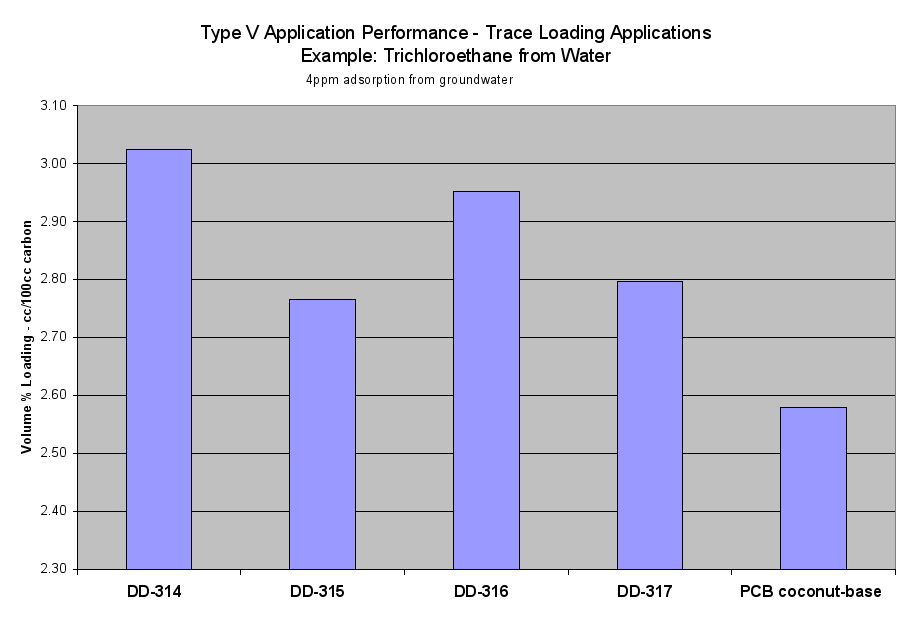

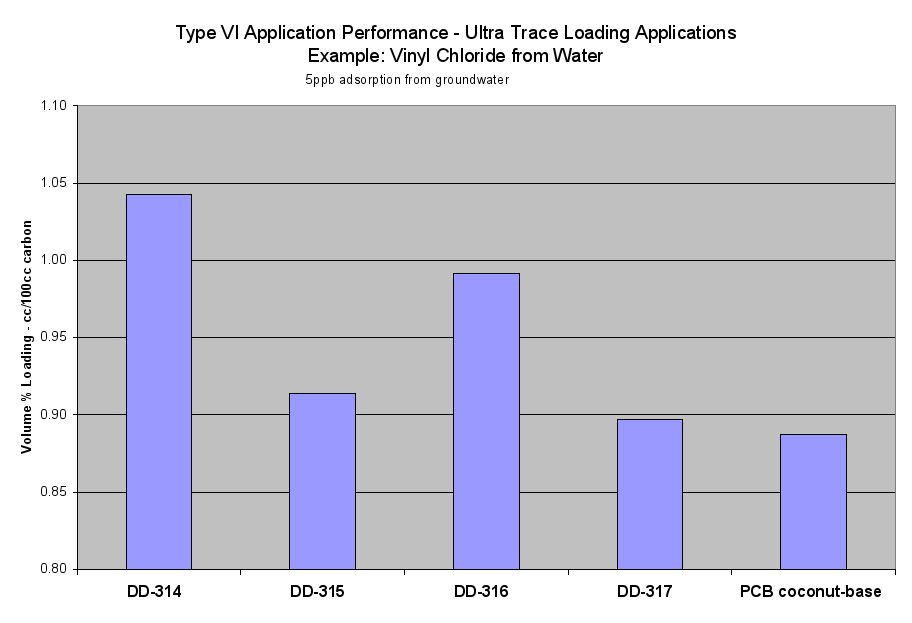

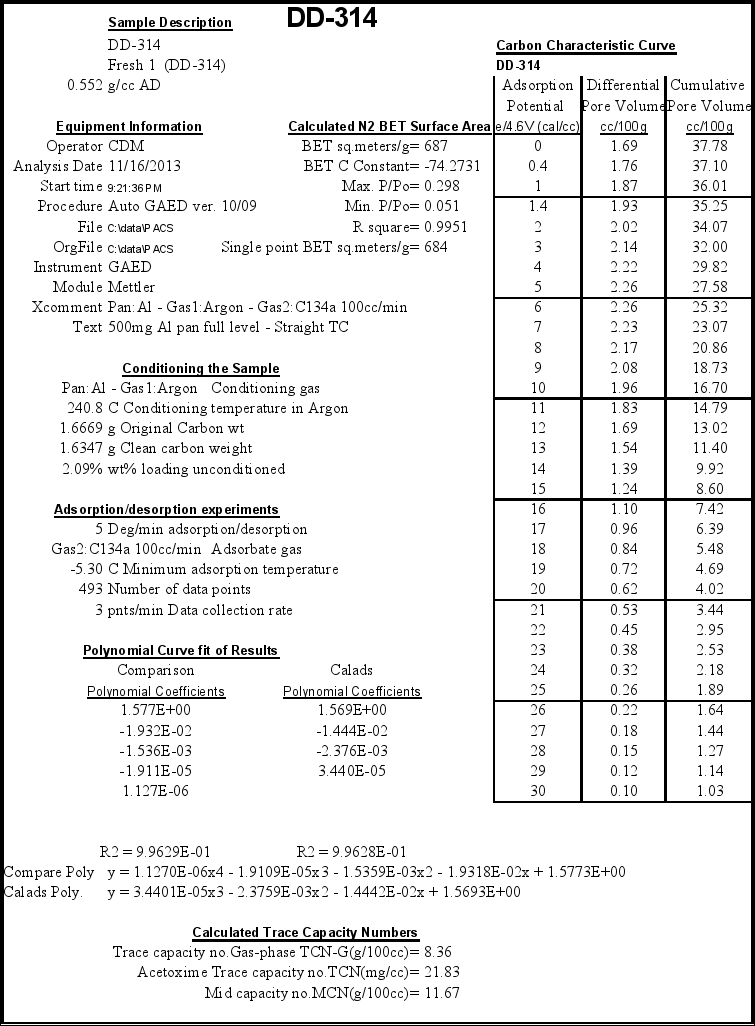

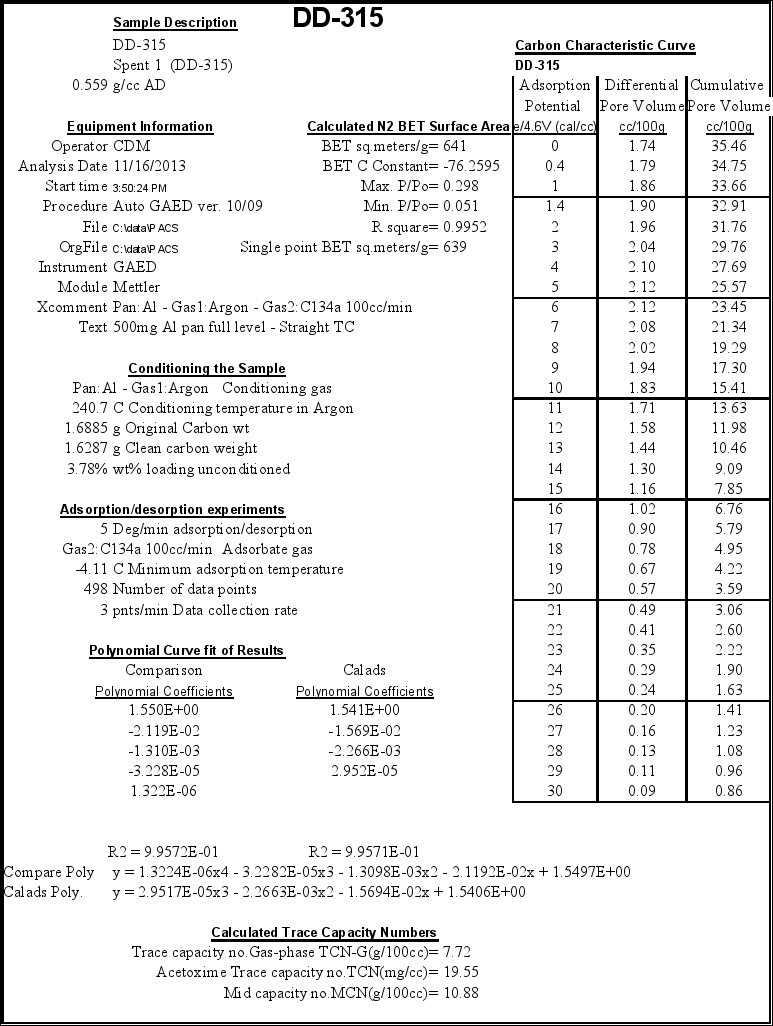

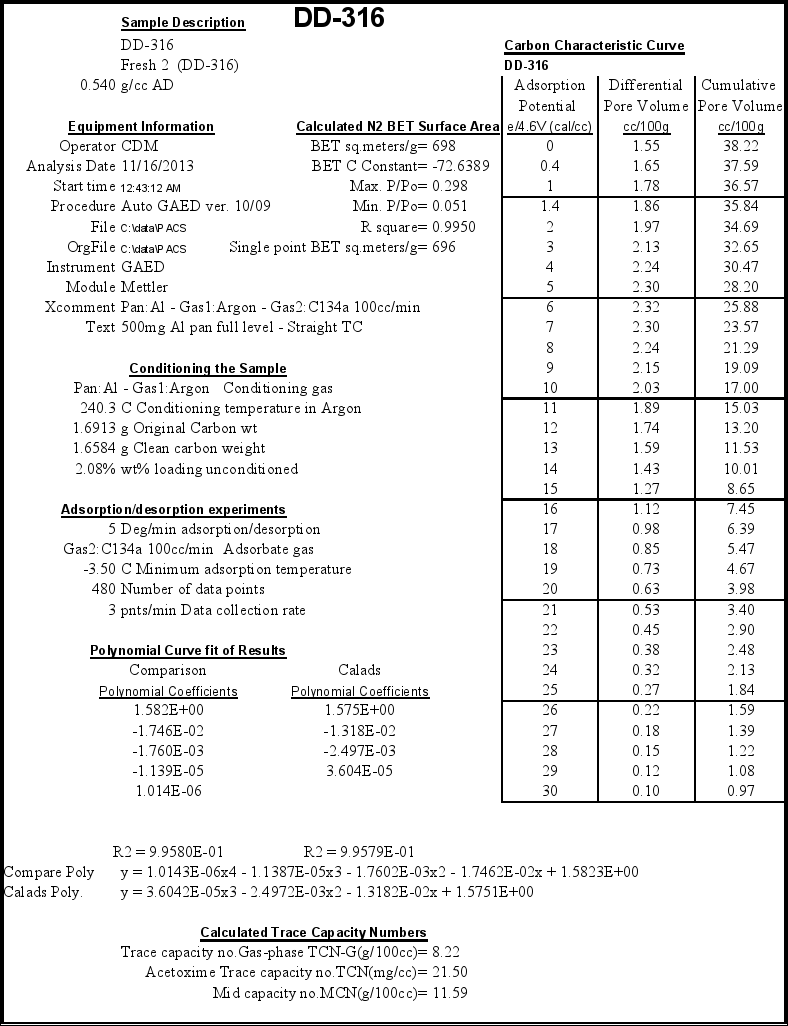

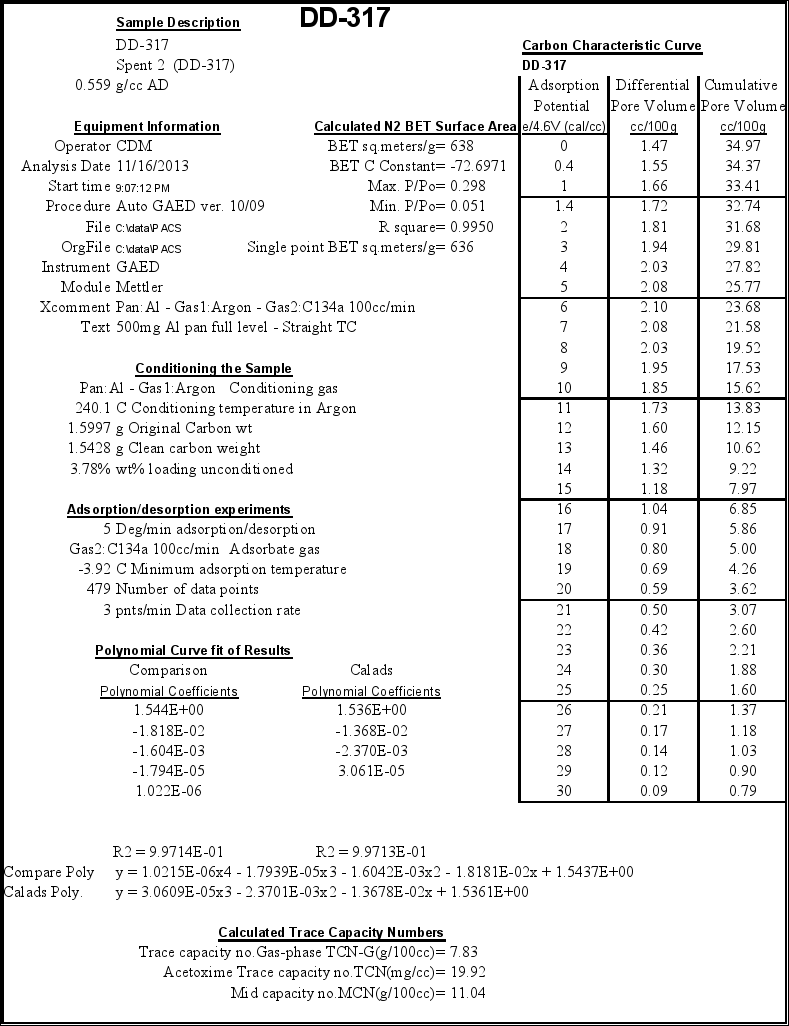

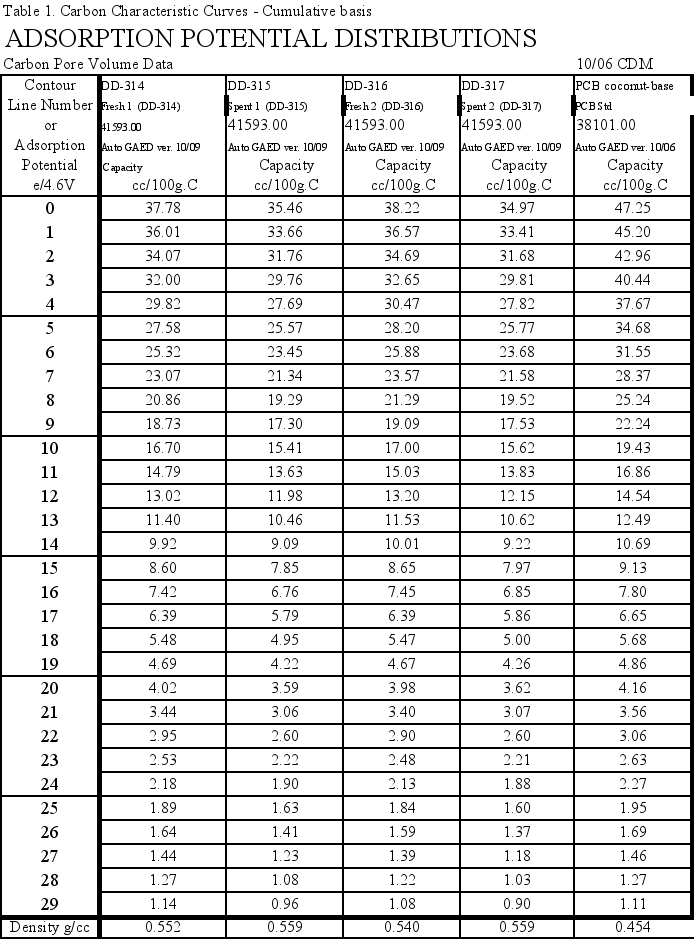

Four samples of granular activated carbon (GAC), Fresh 1 (DD-314), Spent 1 (DD-315), Fresh 2 (DD-316) and Spent 2 (DD-317) were fully characterized for Aqueous phase comparison using the Gravimetric Adsorption Energy Distribution method (GAED). The samples were compared to a PCB Coconut-based reference carbon of about 1200-iodine number. The Apparent Densities (AD’s), determined by using the ASTM D-2854-96, were 0.552 g/cc, 0.559 g/cc, 0.540 g/cc and 0.559 g/cc, respectively, and made volume-based comparisons possible. The samples lost between 2 and 4 weight percent on conditioning (heating the samples to 240ºC in argon and holding for 25 minutes) indicating they had picked up little from their surroundings like humidity or an oxidizing substance. The two Fresh samples were very similar in activity and structure as were the two Spent samples. However, the Fresh samples had about 8% greater total adsorption pore volume than the Spent samples. The calculated BET surface areas indicated that the Fresh 1 and 2 samples had a surface area of 687 sq.meters/g and 698 sq.meters/g, respectively, while the Spent 1 and 2 samples had surface areas of 641 sq.meters/g and 636 sq.meters/g, respectively. The Differential Characteristic Curves showed the structures of these samples to be similar to that of PCB reference carbon. Graphs of the isotherms MTBE, Benzene and Phenol showed similarity to the PCB reference except in the higher concentration areas. In the six Application Performance Types, the Fresh samples out-performed the Spent samples in all six Types but especially in Type III (Moderate Loading Applications like Benzene Vapor from Air), Type IV (Regenerable Trace Loading Applications like Acetone Solvent Recovery), Type V (Trace Loading Applications like Trichloroethane from Water) and Type VI (Ultra Trace Loading Applications like Vinyl Chloride from Water). Microscopic photographs of these samples are available upon request.

GAED Results:

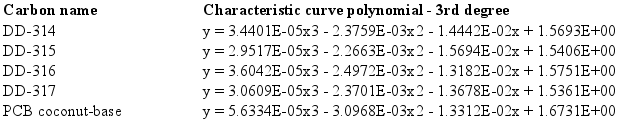

Samples Fresh 1 (DD-314), Spent 1 (DD-315), Fresh 2 (DD-316) and Spent 2 (DD-317) were fully characterized for aqueous-phase GAED by measuring the entire characteristic curves. The Apparent Densities (AD’s) of 0.552 g/cc, 0.559 g/cc, 0.540 g/cc and 0.559 g/cc, respectively, were used allowing volume-based results. PACS Laboratories routinely run ASTM D-2854-96 for Apparent Densities before GAED full characterizations. The carbons were then compared to a PCB coconut based reference carbon that had been commercially activated.

The samples were run in granular form. A summary of the actual test data and conditions used is listed in the data summary table at the end of the report in Appendix A. On conditioning (heating the samples to 240ºC in argon and holding for 25 minutes,) Fresh 1 (DD-314) lost 2.09 weight percent, Spent 1 (DD-315) lost 3.78%, Fresh 2 (DD-316) lost 2.08% and the Spent 2 (DD-317) lost 3.78%. Losses of less than 8 percent indicated a well-stored sample that had been protected from the small amount of moisture pick-up from ambient air during handling and storage and were also fresh and not oxidized. All samples had well under 8% weight loss indicating they were clean carbons that were protected (stored in a proper containers) from oxidation or picking up humidity. All activities and adsorption capacities were calculated on a clean carbon basis. To observe these capacities in the field may require additional processing of the carbons on site.

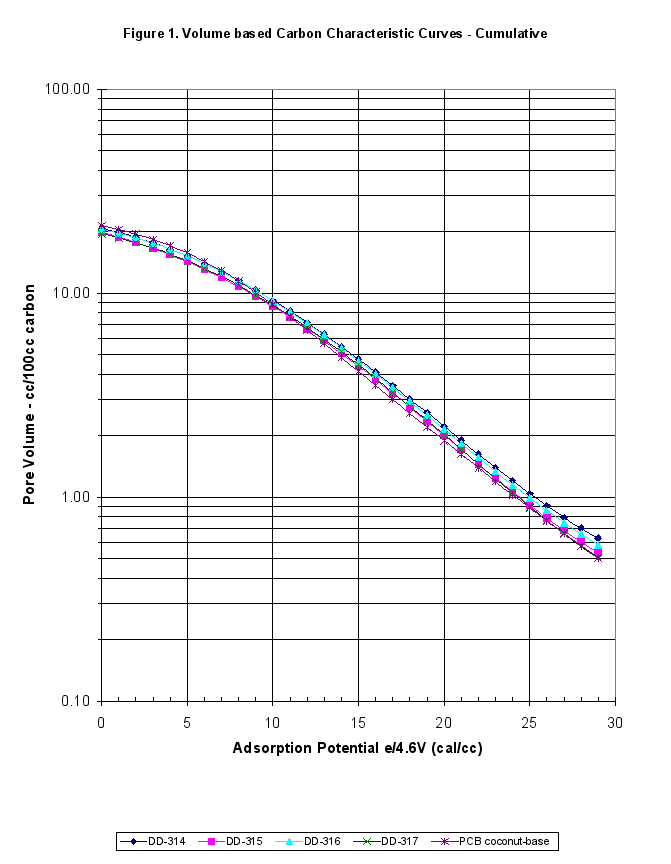

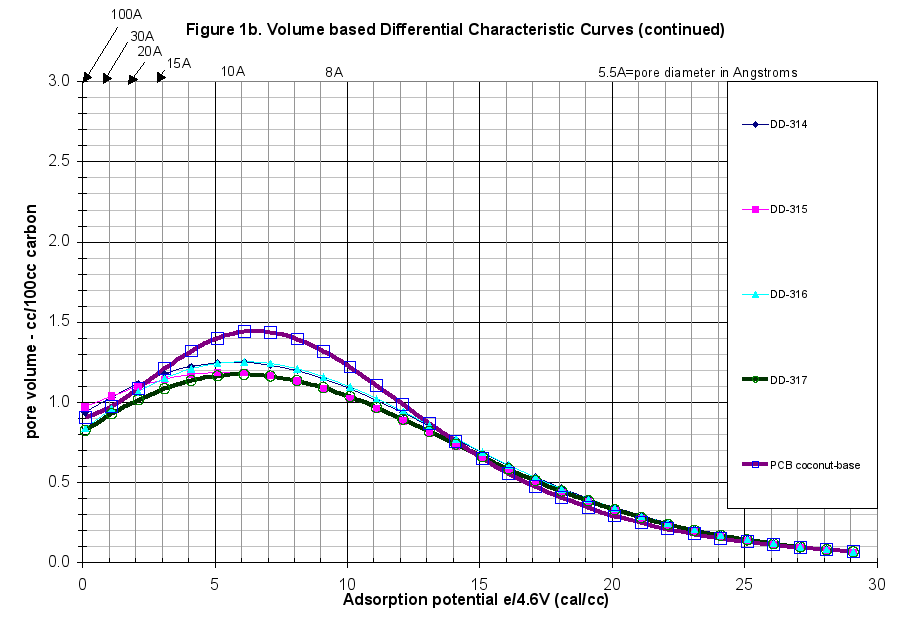

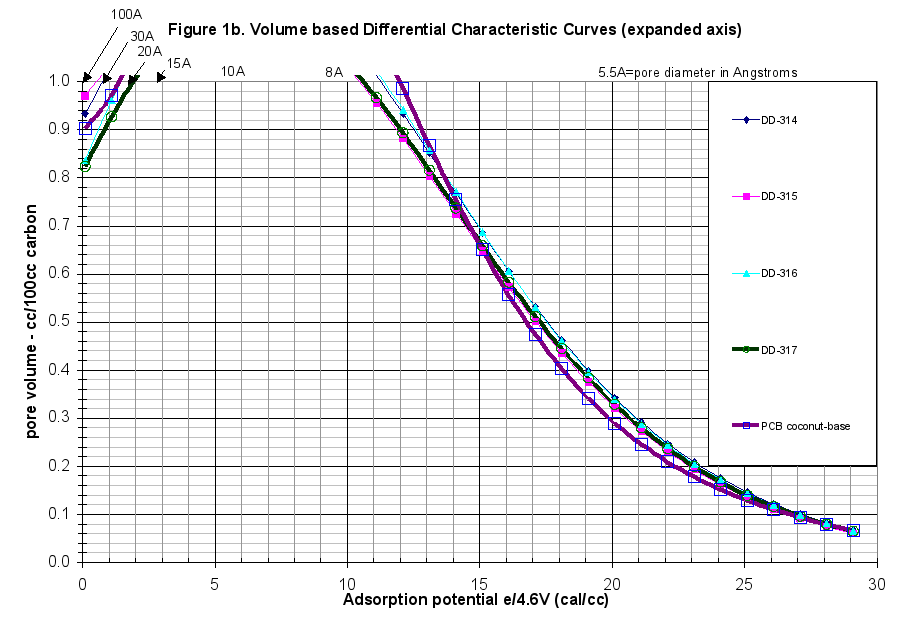

The GAED runs were typical. The difference between the adsorption and desorption curves was minor throughout the experiment, therefore there was no hysteresis present, as was normal for commercially activated carbons. This report extends the comparison of these carbons beyond just the presentation of the characteristic curves. The plots of the differential and cumulative characteristic curve data are presented in Figures 1 and 1b in a volume-based comparison. Weight-based comparisons are also available. The specific run data and results are attached as Appendix A.

GAED Raw Data

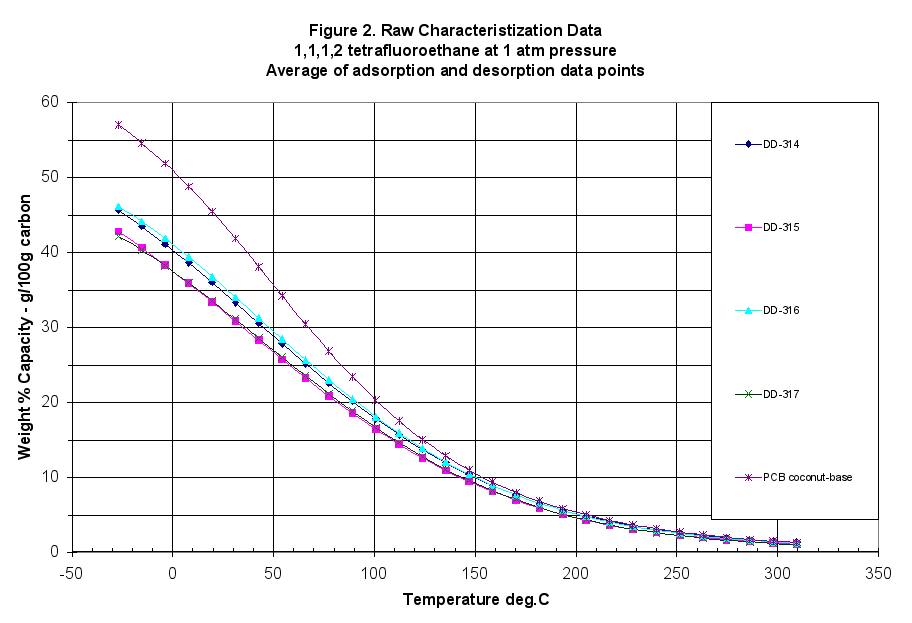

The GAED (gravimetric adsorption energy distribution method) measured almost 500 adsorption and desorption data points each, covering seven orders of magnitude in relative pressure (isothermal basis) and three orders of magnitude in carbon loading. The mass adsorbed was also divided by the carbon mass to generate a weight percent loading for easier comparison. The raw data is plotted in Figure 2. At 240ºC, the adsorbent gas C134a or 1,1,1,2-tetrafluoroethane was introduced and the loading increased. Note in Figure 2, the mass loading was plotted against temperature but the relative pressure was also changing. There were three variables affecting performance that changed from point to point: vapor pressure, partial pressure, and temperature.

To make comparisons easier, the large data file of adsorption/desorption points at different temperatures and relative pressures was simplified. First the data was interpolated to get 30 evenly spaced points covering the entire data range. Next the adsorption and desorption results were averaged to get the equilibrium values (the difference between adsorption and desorption was minimal for this sample – no hysteresis). The y-axis was converted to pore volume measures, in cc liquid adsorbed or cc pores filled/100grams carbon, instead of weight percent. The average interpolated data for these characteristic curves is presented in Table 1, and Figures 1 and 1b.

Performance Prediction Models

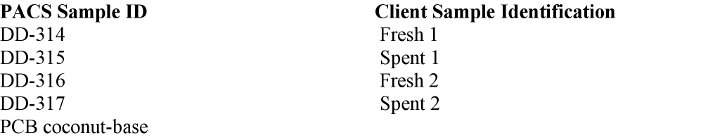

These curves are the only carbon related information required to predict physical adsorption performance using Polanyi Adsorption Potential theory. These single and multicomponent, gas and liquid phase, computer models are used to predict carbon performance and are available from PACS. To do performance predictions the following polynomial describes these carbon samples:

In the equation, y was the common logarithm of pore volume in cc/100g carbon and x was the e/4.6V adsorption potential in cal/cc. Characteristic curve polynomials are also listed in Appendix A.

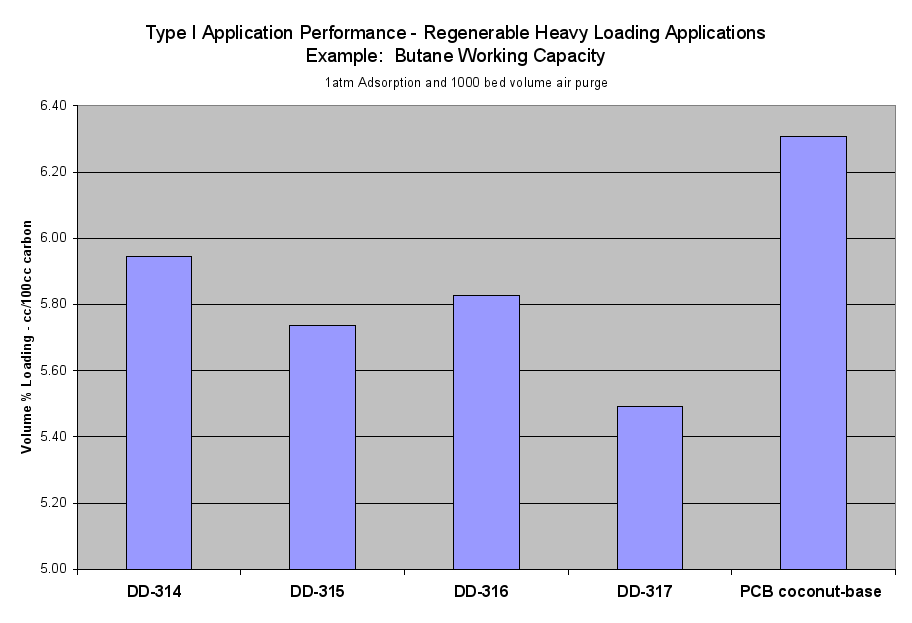

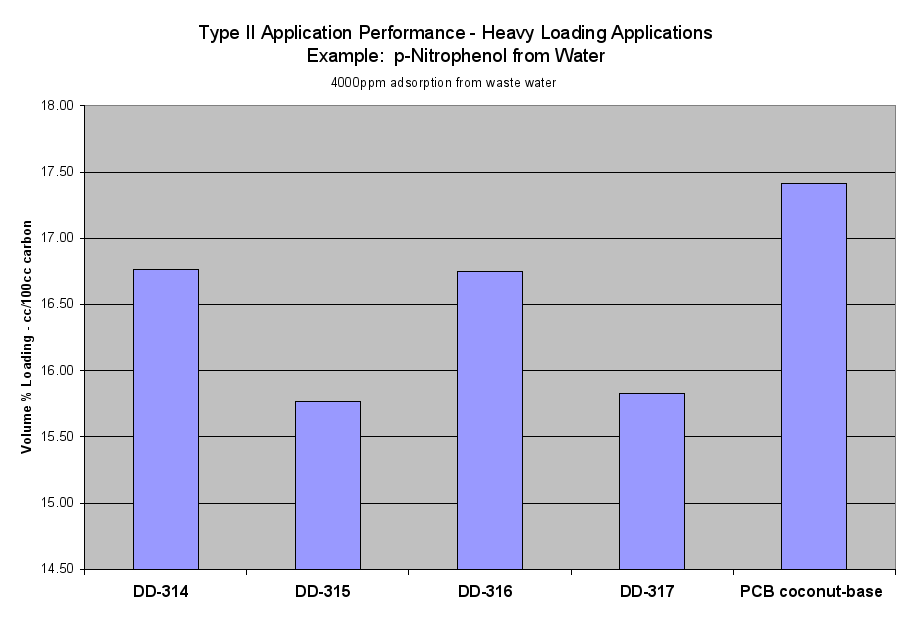

Performance in the Six Types of Applications

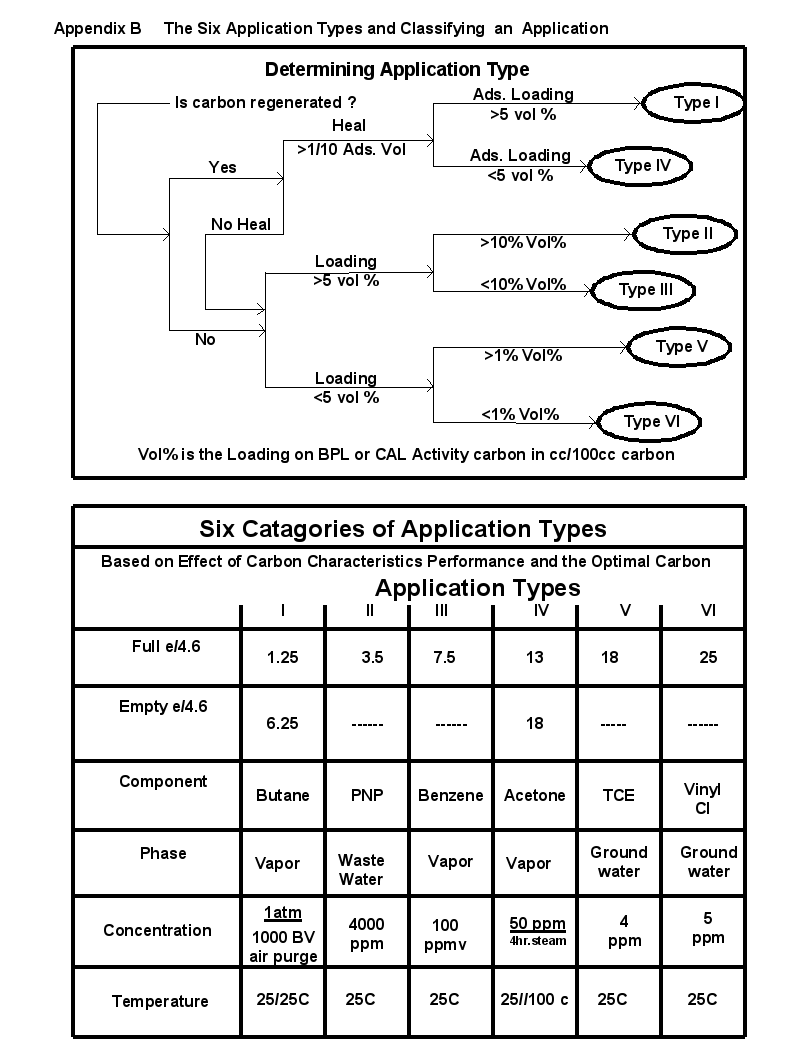

The simplest comparison of carbon for a specific application is to run the performance prediction calculations for specific conditions, concentrations, and components present in the application. However, our experience with years of carbon optimization and performance comparisons has found that all physical adsorption applications can be placed into six application types. The proof is part of a 16-hour/800 slide-training course on carbon fundamentals given by PACS at least once a year.

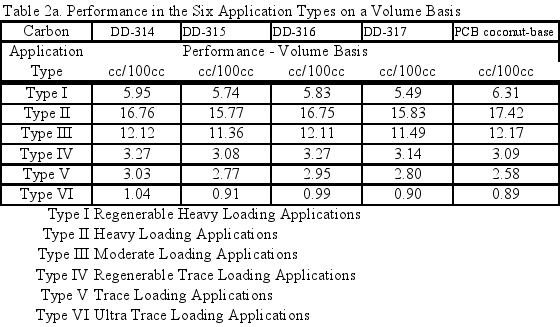

The comparative results in Table 2a demonstrate the value of the different carbons for use in the different types of applications on a volume basis. For a given application type, the results are related to the amount of carbon required to get a certain level of performance. Therefore, a carbon with twice the cc/100g adsorption performance in an application type required half the pounds of carbon to achieve a level of performance in that application type.

Table 2a compares performance on a volume basis and gives the values of the comparative results for the sample carbons versus the performance for the standard commercial carbons for the six application types. These results can also be provided on a weight basis if desired.

A series of two slides are attached as Appendix B, which describe the 6 application types and the classification process to determine what is the application type. Wastewater applications tend to be Type II or Type III. Municipal water purification varies from Type III, Type IV or Type V applications. Removal limits are not low enough and analytical testing is not sensitive enough at this date for Type VI. (Purifying hydrogen of CO and N2 at room temperature is one of the few current Type VI applications). Municipal plants with surface water sources tend to be Type III or Type IV. Plants with ground water sources tend to be Type IV or V.

Trace Capacity Numbers

The characteristic curves were used to predict the values for the acetoxime trace capacity (TCN), gas-phase trace capacity number (TCNG) and mid capacity number (MCN). These results are presented at the bottom of the summary pages in Appendix A.

Adsorption Isotherms

The characteristic curves are also translated into adsorption isotherms using the programs mentioned above: Figure 3 for MTBE (weakly adsorbed material), Figure 4 for benzene (more strongly adsorbed species) and Figure 5 for phenol at pH=7 (quite strongly adsorbed material).

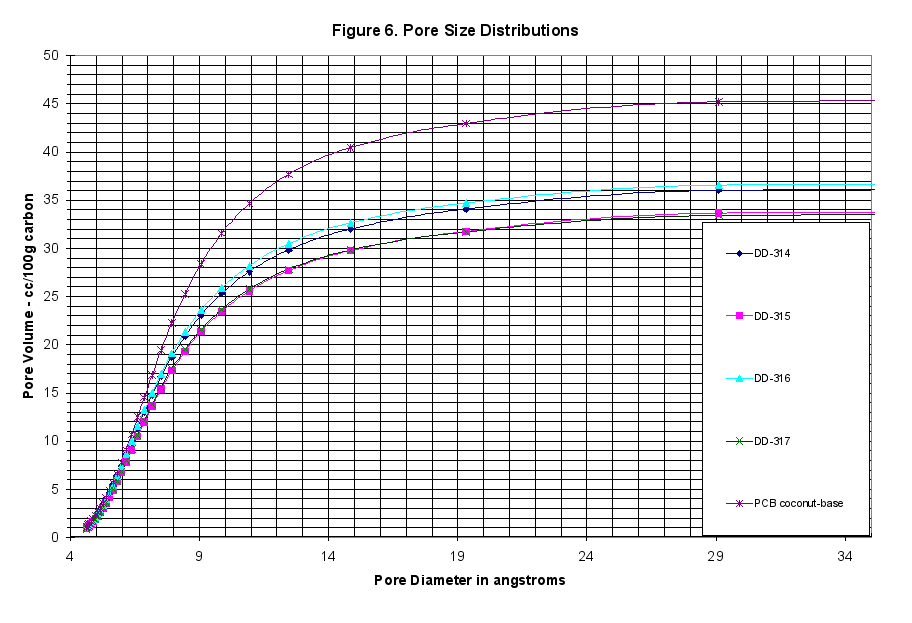

Pore Size Distributions

The Kelvin equation, modified by Halsey, can be used to convert the characteristic curve data to calculated BET surface areas or pore size distributions. This is not useful in terms of performance evaluations, but some audiences are more comfortable with the concepts of pore radius and a series of capillary sizes when thinking about activated carbon. Figure 6 shows the cumulative pore size distributions, which we include but find of little use. The single and multi point BET surface area was calculated from these curves and is presented in the Summary Tables in Appendix A.

Interpretation of the GAED results:

- Four samples of GAC were fully characterized for aqueous phase comparison by GAED (gravimetric adsorption energy distribution method): Fresh 1 (DD-314), Spent 1 (DD-315), Fresh 2 (DD-316) and Spent 2 (DD-317).

- The samples were compared to a commercially available PCB Coconut-based carbon of about 1200 iodine, on an aqueous phase basis.

- The AD’s, determined by using the ASTM D-2854-96, were 0.552g/cc, 0.559g/cc, 0.540g/cc and 0.559g/cc, respectively, and made volume-based comparisons possible.

- On conditioning both Fresh samples, 1 (DD-314) and 2 (DD-316), lost about 2.1 weight percent. The two Spent samples, 1 (DD-315) and 2 (DD-317), lost about 3.8% by weight indicating they were all relativity clean and dry (Data Summary Table Appendix A).

- Conditioning entailed heating the samples to 240ºC in argon and holding for 25 minutes so that all activities and adsorption capacities were calculated on a clean carbon basis.

- The two Fresh samples were within 1% of each other in total adsorption pore volume: 37.8cc/100g carbon for DD-314 and 38.2cc/100g carbon for DD-316 (Table 1).

- The two Spent samples were also, within 1% of each other in total adsorption pore volume: 35.5cc/100g carbon for DD-315 and 35.0cc/100g carbon for DD-317 (Table 1).

- The Fresh samples had about 8% greater total adsorption pore volume than the Spent samples.

- The calculated BET surface areas indicated that the Fresh 1 and 2 samples had a surface area of 687 sq.meters/g and 698 sq.meters/g while the Spent 1 and 2 samples had a surface area of 641 sq.meters/g and 636 sq.meters/g (Data Summary Table Appendix A).

- The Differential Characteristic Curves in Figure 1b showed that all the samples had a similar structure to that of the reference PCB material.

- Graphs of the calculated aqueous-phase isotherms, included in this report, showed how these samples would perform at different concentrations of MTBE, Benzene and Phenol (Figures 3, 4 and 5).

- Both the Fresh samples performed very well in four of the six Application Performance Types: Type III (Moderate Loading Applications like Benzene Vapor from Air), Type IV (Regenerable Trace Loading Applications like Acetone Solvent Recovery), Type V (Trace Loading Applications like Trichloroethane from Water) and Type VI (Ultra Trace Loading Applications like Vinyl Chloride from Water).

- Microscopic photographs of these samples are available upon request.

Appendix A.

GAED Summary Tables

For other laboratory testing service, method development, R&D, software or consulting service needs, contact:

George@pacslabs.comTELEPHONE: (+1)

For Carbon Conferences or Short Courses in public sessions or at your time and place, contact us.

PACS provides testing, courses and consulting at the client's time and place, and twice a year carbon conferences.

PACS Positions Available:

- Laboratory chemist for activated carbon group. Will train!

PACS has positions available for professional scientific service providers and has provided these services for over 38 years. PACS will accept proposals for short courses, consultants, activated carbon conference directors for focused conference subjects, and other needed services. New ideas are welcomed.

PACS, Inc.

409 Meade Drive

Coraopolis, PA 15108

PACSlabs.com